Wet grinding mills also referred to as media mills are used to reduce particles in liquids. The mills make it possible to break down, what are known as agglomerates into their finer individual particles. This increases color development, gloss transparency, particle size distribution and can even increase chemical activity. Agglomerate is a group of particles that have strong bond holding them together that can only be broken by a relatively strong mechanical shear.

Custom Milling & Consulting LLC, located in Fleetwood, PA is a manufacture of wet grinding mills and provides toll milling services to a wide range of industries. We manufacture a horizontal media mill, the SuperMill Plus. It can be equipped with different materials of construct, a wide range of features, and fitted with our SMART package technology. Our staff of engineers will take the time to understand your processing needs and customize the milling equipment to your specifications.

How the wet grinding mill works.

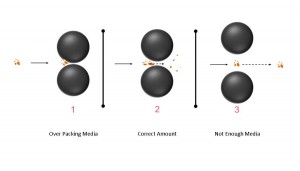

Each mill is assembled with a control panel, motor, and a horizontal chamber that contains the discs and spacers. The chamber is filled with media, but you want to be sure not to over pack or use to little. Size of the media and amount used depends on your application and the results you want to achieve. As the shaft inside the chamber with the discs and spacers mounted rotates at high velocity agitating the media.

As the liquid is fed into the chamber and passes through the moving media the agglomerates come in contact with surfaces inside. Large clusters are pushed through the small space forcing them to squeeze. Pressure from the tight fits begins to fracture the bonds and as the particle reaches the end of the surface area the pressure is released causing the agglomerate to disperse.

The illustration shows how shearing occurs and what happens if you over pack the chamber with media or use too little.

Particles can also disperse when they impact other particles in motion of the rotating surface areas. CMC mills can produce sub-micron particle sizes and disperse them evenly and consistently through out the materials.

Contact us at CMC to talk to us about our wet grinding mills and how we can assist your company at sales@cmcmilling.com.